Having said that our Catamarans are based on highly efficient, high performance displacement hulls (fuel efficient), we would like to elaborate with the following:

Our hulls are slimmer than the average power cat – the norm for the average power cat being a Waterline Length to Hull Beam Ratio of approximately 10.

To compare, as an example, the norm of the average power cat with our Supercat 38 Sport Custom, the following can be seen:

Average power cats of the same size category as the 38 Sport (11,7m) would be 11,7m length, with a Hull Beam of roughly 1,17m (Per Hull).

The 38 Sport Custom with a Waterline Length of 11,7m has a Hull Beam of 0,6m (Per Hull) and 0,8m at the hulls knuckle.

This results in a Waterline Length to Hull Beam Ratio of 19.5 for the Supercat 38 Sport Custom

Another important aspect of performance is the Displacement to Length Ratio (Takes weight into consideration):

The formula for Displacement to Length Ratio is as follows:

Displacement to Length Ratio = Displacement / (0.01 X WL X 3)

The lower the resultant number, the more fuel efficient the boat is.

Displacement is the displacement in long tons (2240lbs)

WL is the Waterline Length in Feet

Examples of Displacement to Length Ratios:

Stiletto (Supercat 38 Sport Custom with Short Deck)

Light (100L Fuel and 2 People) Displacement to Length Ratio = 2.24

Loaded (550L Fuel, 8 People, 500kg Crew Effects) Displacement to Length Ratio = 3.45

Drop UR Rods (Heavily Spec’ed Supercat 38 Sport Custom with Long length Deck)

Light (100L Fuel and 2 People) Displacement to Length Ratio = 2.99

Loaded (550L Fuel, 8 People, 500kg Crew Effects) Displacement to Length Ratio = 4.20

From this, it can be seen that light weight structures and an overall lightweight boat are at the forefront of our design.

In this respect, we believe it would be of interest to view the article by John Shuttleworth at the following link:

http://www.shuttleworthdesign.com/adastra-article-part1.html

While the Adastra article relates to boats in a larger size range, it will be a useful comparison to see how advanced the Supercat designs measure in comparison.

From all of the above, one becomes aware that low weight construction, and carrying the bare minimum aboard, enhances the performance and reduces fuel consumption.

To re-enforce the above statements, this is the formula we use to predict the performance of our boats:

The 38 Sport was originally designed to run as a light weight hull, running on a pair of 50hp, for best performance and fuel efficiency.

A boat such as Stiletto is an example:

This boat had a fuel economy of approximately 1L per NM at around 10-15knots.

A review of this particular boat, by Ski-boat magazine will make for an interesting read: http://www.africanangler.com/sb_boat_tests_view.asp?id=22

Over the years, this model has however evolved, dictated by the customers’ requirements. Most buyers of these boats are charter fishing type lodges, wanting a day boat which can run a good number of people out for a day’s game fishing, with enough comforts to keep the guests happy. This has meant that the boats have become heavier and heavier, with seating modules, bait tanks, tuna tubes, fighting chairs, outriggers, fridges etc etc. being added. To compensate for the extra weight added, bigger outboards are requested, reaching the maximum limit of 100hp, to achieve the same kind of performance as the light boat with 50’s. The extra horsepower adds to the weight of the boats. These heavier boats, needing more horsepower, have resulted in fuel economies increasing to around 1.7L per NM.

The day boat charter type applications are less affected by this, due to the boat being able to refuel regularly, when needed. In a case where one wants to do long runs though, this has a large effect on the fuel needed to carry etc.

Below are some pics which show examples of lighter construction materials used, borrowed from the aeronautical industry, to help reduce the construction weight on some of our custom boats.

About 35 years ago, we played with hydrofoils on a small planning hull catamaran.

This boosted its performance from 30knots to 50knots.

Dennis (Supercat Marine’s Founder), has had an interest in ultra-light aircraft and the design of light aircraft. This being influenced to some extent by a friendship with retired lady who was a designer / aerodynamicist for NASA and Boeing. This led to more knowledge gleaned in hydrofoils.

We recently, in the interest of testing to see whether hydrofoils would be beneficial to our displacement boats, fitted a 38 Sport Custom and Caldera 34, with hydrofoils for testing. These hydrofoils were designed to generate lift of 1,850kg at 20knots, thus partially lifting the hull and gaining performance by reducing the wetted area.

Performance is greatly enhanced in the 15-20 knot range regarding stability, comfort of ride and an even drier boat, due to the lift of the bows.

The trade-offs, however, are possibly the nuisance factors of the foils in terms of fishing lines and anchor ropes, and, with the complication of foil installations, it has led us to believe that they should only be applied in very specific applications.

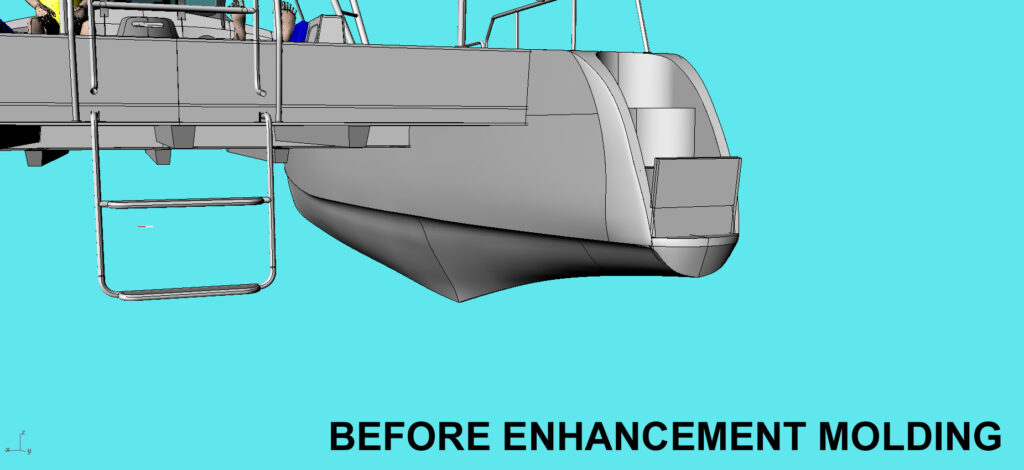

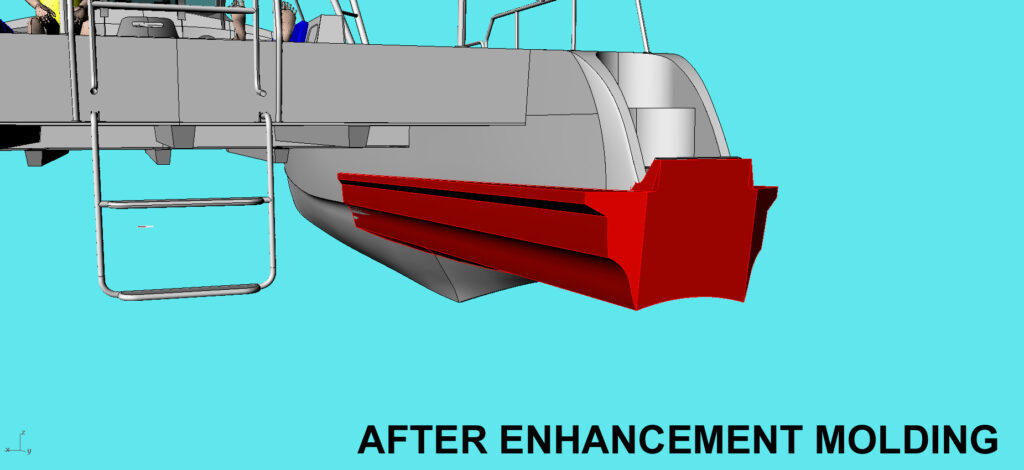

Our exploits with foils has led us to looking at enhanced floatation in the stern of the 38 Sport Custom, where 100Hp outboards and large fishing crew tend to squat the stern.

The enhancement is a molding which can be bonded to the last 5m of the hull, adding approximately 150kg of additional buoyancy per side (300kg total) near the stern.

The shape has been enhanced to a design somewhere between a Canoe Stern and an American patent of Schultz Reverse Dead Rise.

We are currently building the pattern for the mould and this upgrade will be available in a few months, obviously after final rigorous testing.